AutoMind, the Free AI Diagnostic Tool, explains your codes clearly — giving you confidence and clarity with any engine issue.

Just pay £4.95 p&p

The Hydrogen Carbon Cleaning technology works by converting a 99% based purified water solution into Hydrogen and Oxygen gases known as HHO or Brown gas. This gas is then administered to a running engine via the air intake. As these gases run through the engine they interact with the carbon deposits burning and breaking them down into tiny particles that will then safely exit through the exhaust.

The process is technically known as pyrolysis – Hydrogen, along with increased oxygen levels, raises the combustion temperature within the engine making it possible for a chemical reaction that burns off and disintegrates the carbon deposits. Now what’s left of the carbon is in a gas form and airborne it exits safely through the exhaust as generally a clear non-pollutant smoke.

Once the restrictive carbon is removed the engine will be able to operate efficiently again.

For many years the old ‘Italian tune-up” trick (a regular quick blast down an open road at high RPMS) would be sufficient to keep the carbon bugs at bay. This helped simply because high engine speeds equal hot engine temperatures, which effectively burnt away the carbon. However, due to engine designs being restricted for lower emissions, the carbon build-up issue is now far worse than ever before so today’s crop of petrol, diesel and hybrid engines don’t respond very well to this technique. Even if they did in this day and age it’s certainly not safe or legal to drive in such a manner, especially with modern traffic conditions.

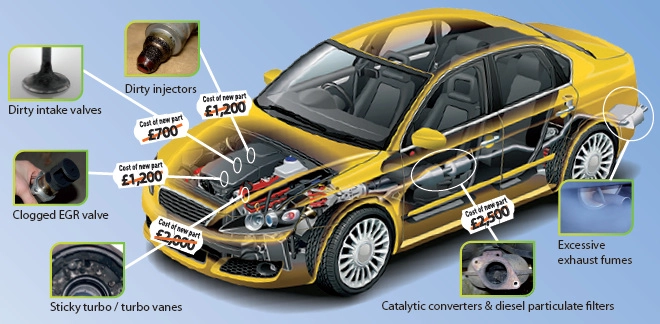

Symptoms manifest in the form of saturated components which will reduce the efficiency of the engine, stifle power, performance and economy, increase emissions and reduce the lifespan of many expensive components such as… Diesel Particulate Filters and Catalytic Converters (cost of new parts and labour as much as £3,500), EGR Valves (cost of new parts and labour as much as £1,200 to £1,500), Turbos (cost of new parts and labour as much as £2,000 to £3,500), Intake valves (manual cleaning costs as much as £1,000), Injectors (cost of new parts and labour as much as £300 each), Intake Manifold and Swirl Flaps (cost of new parts and labour as much as £2,000), Oxygen Sensors and Spark Plugs.

What makes our CarbonCleaning machine unique? It’s the only hydrogen engine carbon cleaning machine worldwide that is truly mobile. Using PowerSystem’s patented technology and unique solution our Carbon Cleaning branded machines don’t require high electrical currents to generate the small amounts of hydrogen for the process of engine carbon cleaning. The machine's process is Totally Green!

Our additional unique staged chemical solutions have been developed and tested in the UK to meet our own levels of satisfaction. They aid in cleaning the injectors, the oily gums, and residues that despite what our competitors will tell you Hydrogen cleaning can’t remove, and to aid the DPF to regenerate successfully.

Be wary of so-called competitors who claim excessive amounts of Hydrogen are required, this is not safe for your engine and has the potential to cause irreversible damage. Unfortunately, it is becoming more commonplace now that this misleading marketing strategy is occurring in the Hydrogen carbon cleaning industry. The brand that we hold sole UK rights for, Carbon Cleaning, are the originators of this technology, they’ve 100’s of machines being used successfully across 50+ countries to produce the desired results on a daily basis. Don’t be duped by copycats with little understanding of what they are doing.

AutoMind explains carbon-related and other fault codes in Plain English — so when you have an engine fault, you'll know exactly what's going on.

Just pay £4.95 p&p

We use cookies to enhance your experience by tailoring content and improving functionality. By clicking 'I Agree,' you allow us to optimize your experience and provide personalized, seamless interactions. Learn More